After my all frustrations with the car back in February I decided to take the car to Ferrari as a last resort to see if they could turn up any issues to solve my mystery stuttering. The long and short of it is that the car has remained there since then (February) and is still undergoing repair, typically awaiting parts.

They have needed to start from first principles and run through a series of standard tests such as:

1. Battery health check

2. Charging system check

3. Fuel pressure check

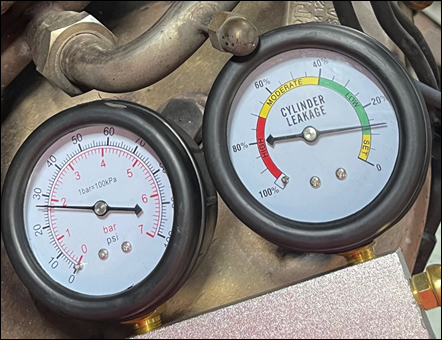

4. Compression check

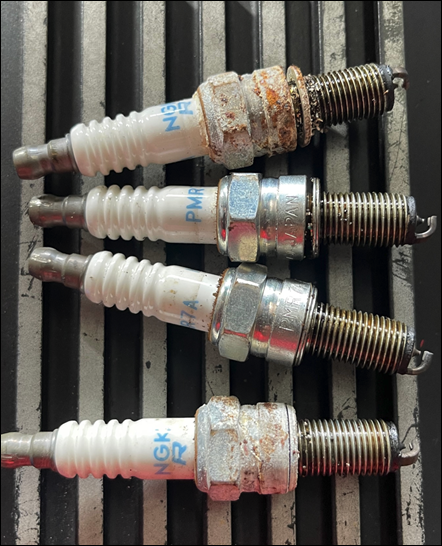

5. Spark check

6. Timing check

7. Gas analysation (this would also confirm catalyser incongruence)

8. oscilloscope on major sensors

9. Heat scanning

10. Testing

The major points that this first pass found where:

1. Rectifying the air leaks at the intake manifold and then re-testing for any further leaks. The Motronic is trying to compensate for this (can be seen by the increased multiplicative fuel trim) and may well be inducing further problems. With the manifold raised it would be advisable to check the synchronisation between the throttle butterflies.

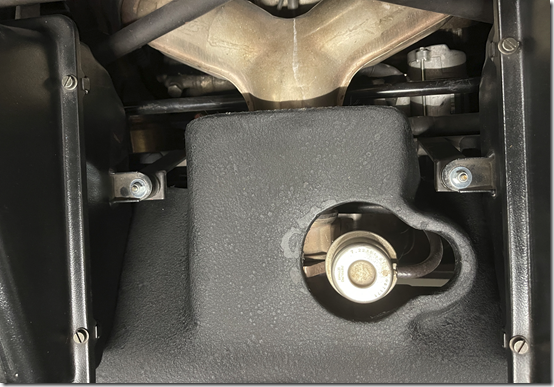

2. Further investigation of the fuel pressure loss occurring after engine shut down. Preliminary testing ruled out a leak through the pressure regulator vacuum lines. The most likely cause would be leaking injectors flooding the cylinders. This would explain why it is hard to start the engine when hot if left for a 30-60 minute period but starts easily if restarted straight away when or if left for an extended period allowing the fuel to evaporate.

Above you can seem some of the results they sent me using a smoke test. This highlighted the air leaks at the intake manifold.

During this time I managed to make contact with Phil Hughes from Ferrari Fixer in Melbourne, who was recommended by another contact. He said:

that they have made no mention of the dual mass flywheel.

When the DM flywheels lose their internal grease damper through natural degrading over time, they then crank with an erratic noisy/dirty electrical signal on the two crank sensors and the cam sensor. When the flywheels are on the verge of this, they can be ok when cold as the remaining grease is sticky and firm, but when hot the grease goes runny, losing damping effect.

I would suggest the car needs a deeper look into the implausible coolant temp readings, but more likely a flywheel service.

There is also the option to delete/lock the DM flywheel and remove the issue permanently. This does cause a slightly less smooth idle than when the flywheel works properly but more often than not the faulty DM flywheel makes the idle more rough than as if it were locked, as it appears in this case as noted in the dealer report.

I had Ferrari check this flywheel grease and they found it was about half the level that it should be, so they sent away for the right grease to repack it. So probably not necessarily the main issue but worth fixing while the car is in the shop as well as eliminating any issues there.

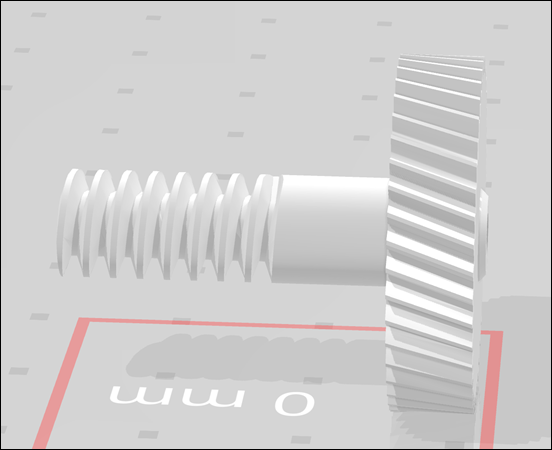

Ferrari then did a check of the injectors and found that some where dripping when closed:

With that identified, it is off to the parts bin to find replacements for these.

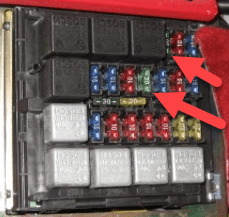

Apart from all that I also need my centre console fixed as well as get my tow hook properly aligned. Turns out that if I had ever needed to use my tow hook it would not have fitted as designed into the front of the car. Part of the body work is just far enough across the hole to prevent the tow hook from aligning and screwing in correctly. It would be doubly painful to have an issue with the car out somewhere far from home and then not be able to use the tow hook to get it onto a flat bed if needed.

Thus, the car has been away now for over three months under going thorough testing and the following items have been identified and are being rectified as we speak:

1. Intake manifold seals (awaiting parts)

2. Repack mass flywheel (awaiting correct grease)

3. Injectors (awaiting parts)

4. Console trim housing

5. Tow hook alignment

It has been disappointing not to have the car but I really don’t want to deal with it if it keeps failing and being as unreliable as it has been. Thus, it is better that it stay away until it is fixed. If I do decide to sell it after all this then it still needs to be fixed as much as possible before then, so all I can do is wait for this repair to complete and then see what happens. I certainly hope that all this resolves the stuttering issues and I’m sure the car will run a lot better when I get it back.

Fingers crossed.